Østerport Station from 1897 was probably created with a terrazzo floor, which has since been replaced by tiles. In the 2019 renovation, it was decided to return to the original terrazzo look with a continuous terrazzo flooring in the station, corridor, staircase and business areas.In fact, the choice of terrazzo also has operational advantages compared to tiled floors, for example. In fact, terrazzo is particularly suitable for high-traffic areas because it is hard-wearing and can withstand the effects of moisture that a station floor, for example, is exposed to.

Copenhagen

Denmark

DSB

2019

4900 ㎡

The challenges of construction

However, there were some risks and construction issues at Østerport Station that challenged the ambition to create one continuous terrazzo floor. The structure is exposed to both static and dynamic loads on a daily basis, in the form of the massive crowds that pass through the station daily and vibrations from passing trains. Therefore, potential crack formation cannot be excluded when having a continuous surface without continuous expansion joints.

A beautiful terrazzo floor for many years

Repairs to the terrazzo floor, both due to wear and due to the static and dynamic loads, cannot be avoided over time, but are unlikely to be more extensive than for a tiled floor. The advantage of terrazzo - unlike a tiled floor, which relies on a particular type of tile - is that you can recreate the mix of cement and stone, and so repair without breaking the style.

In this way, we succeeded in creating a coherent expression in the pavement at Østerport Station that is both aesthetic and hard-wearing, and will therefore be functional for many years to come.

Measures against crack formation

- SKT reinforcement in the deck slab, ensuring that deformations from shrinkage, creep and temperature variations in the new deck slab are distributed evenly instead of major single and more pronounced crack formations.

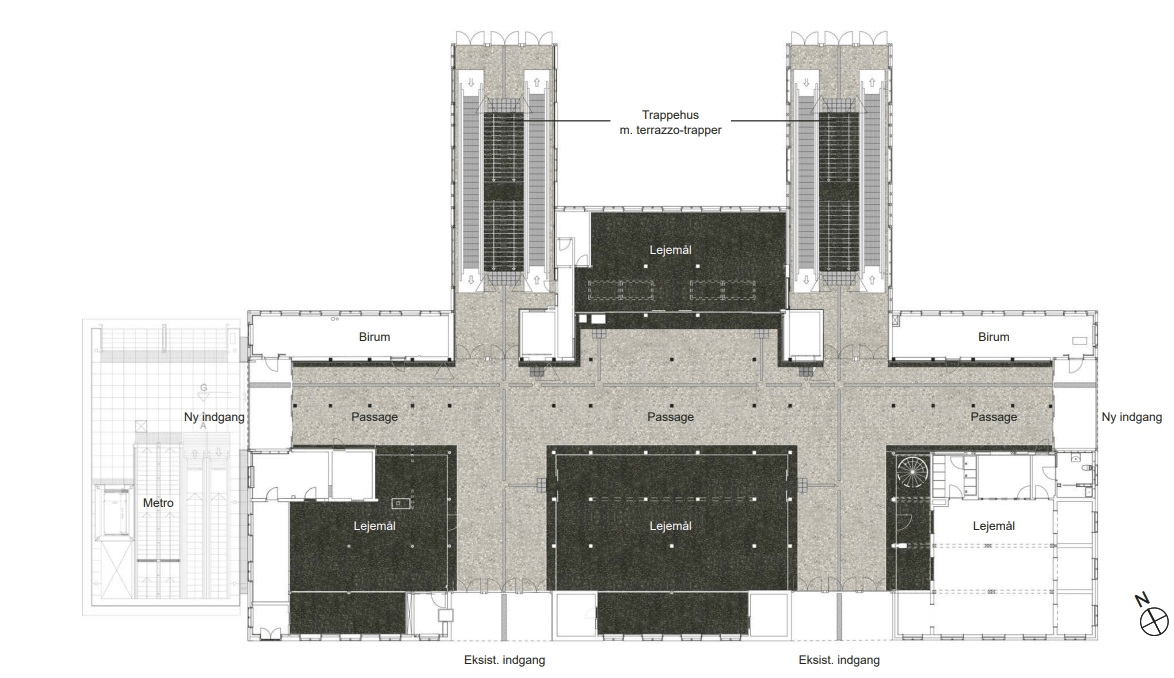

- Field division by casting the cover slab in staggered fields so that the field division of the terrazzo coincides with the underlying structural bearing lines.

- Laying of double aluminium rails at the upper edge of the terrazzo covering.

- Laying of polystyrene between cover plate and columns and an elastic joint in the terrazzo itself

The reinforced construction

A concrete base cast on a permanent formwork of so-called "dovetail plates" helps to reinforce the new floor structure. To ensure good adhesion between the terrazzo and the reinforced concrete slab, no slip layer has been applied between terrazzo and concrete, which means that the terrazzo covering will follow the movements of the concrete slab. The floor thus currently consists of a terrazzo layer of approximately 20 mm thick, laid on top of a new base layer of approximately 80 mm of reinforced concrete - with stainless steel reinforcement. The terrazzo floor is cast in two different colour shades, separating the business areas from the public zones where passengers move through the station.